Keeping windows sparkling clean is essential for maintaining a bright and inviting home, and the best window cleaning tools can make all the difference.

But with so many options available, including innovative cleaning solutions and reliable vacuum cleaners, how do you choose the right window cleaner?

This article explores the ins and outs of window cleaners, from what makes a quality product to the ingredients you should avoid, ensuring you have the best cleaning performance.

It also covers different types of cleaners, the best choices for various surfaces, user-friendly features, safety measures, and some DIY solutions.

Get ready to transform your window cleaning routine with effective cleaning products and practical cleaning tips!

What Is Window Cleaner?

A window cleaner is a specialised cleaning solution or device designed to remove dirt, grime, and streaks from glass surfaces, ensuring a sparkling finish that enhances visibility and aesthetics. Trusted brands like Kärcher and Vileda offer tested window cleaners with remarkable cleaning efficiency.

Utilising modern cleaning tools, such as effective window vacuums and environmentally friendly products, these cleaners not only make the task of cleaning windows easier but also help maintain the longevity of the glass, ensuring quality results.

Trusted brands have developed various formulations and gadgets to cater to different cleaning needs, making window cleaning a doddle for both professional window cleaners and household chores.

What Makes A Good Window Cleaner?

A good window cleaner is characterised by its cleaning performance, ease of use, and ability to deliver quality results without leaving streaks or residues behind. Quality cleaning tools and cleaning product features enhance the overall experience and visibility in your spaces, making them essential for maintaining a polished look all year round.

When selecting the right tools, it's crucial to consider their user-friendly features, such as ergonomic grips and lightweight designs, which can reduce fatigue during long cleaning sessions, especially when tackling high windows.

Joining online communities can help you access reliable independent reviews from sources like The Independent and Good Housekeeping Institute, allowing you to make informed decisions about the products that suit your specific needs. For instance, brands like Windex and Ecover are renowned for their effectiveness and environmentally friendly ingredients.

Not only do these products cleanse glass surfaces with remarkable clarity, but they also tend to incorporate practical tips for use and cleaning expertise, ensuring that each application delivers optimal results.

Remember to always follow the manufacturer's guidance for the best practices in achieving streak-free finishes and cleaning windows efficiently.

What Ingredients Should Be Avoided In Window Cleaners?

When selecting window cleaners, it’s crucial to avoid certain ingredients that can harm both the environment and the glass surfaces. Products containing harsh chemicals may provide short-term cleaning benefits but can lead to long-term damage and poor cleaning performance. Eco-friendly products that are free from harmful substances not only contribute to safer cleaning techniques but also promote sustainability, making them a preferred choice among trusted brands.

Common harmful ingredients often found in conventional window cleaners include ammonia, which can produce toxic fumes, and phthalates, linked to reproductive health issues. Not only can these chemicals irritate skin and eyes, but they can also negatively impact indoor air quality.

In contrast, eco-friendly alternatives utilise natural ingredients like vinegar and essential oils, which effectively cut through grime while being gentle on surfaces and safe for users and pets alike, promoting cleaning without chemicals.

- Vinegar: A natural degreaser.

- Essential oils: Provide pleasant scents and added cleaning power.

- Biodegradable surfactants: Help lift dirt without leaving toxic residues.

By switching to these safer options, users not only protect their health but also contribute to a healthier planet by choosing eco-friendly products.

What Are The Different Types Of Window Cleaners?

Window cleaners come in various forms, each designed to meet specific cleaning needs, from traditional solutions to innovative window cleaning gadgets. Among the most popular types are portable cleaning tools such as effective window vacuums, which quickly remove moisture and dirt from glass surfaces, and versatile steam cleaners that can also tackle stubborn grime on multiple surfaces, enhancing cleaning efficiency.

Each type offers unique benefits and can be a game-changer for those looking to achieve spotless, sparkling glass with minimal effort, using easy cleaning methods.

Ammonia-based Window Cleaners

Ammonia-based window cleaners are widely recognised for their ability to cut through tough grime and deliver cleaning efficiency, making them a popular choice among both professional and DIY cleaners. These cleaners work by breaking down dirt and residues, often resulting in a streak-free finish on glass surfaces, which is essential for maintaining clear visibility and aesthetics.

While the effectiveness of these cleaners is undeniable, there are certain considerations users should be aware of. For instance, ammonia can produce strong fumes, which may be irritating to the eyes, nose, and throat when inhaled. Safety precautions are crucial; always ensure adequate ventilation when using these products. They can cause damage to certain surfaces, such as wood or fabric, so users must be cautious and read labels carefully.

- Pros: Excellent for tackling stubborn stains.

- Cons: Can be harmful if not used properly.

- Always wear gloves to protect your hands.

- Consider using a diluted solution for everyday cleaning tasks, ensuring cleaning without chemicals.

By implementing these practical cleaning tips, users can maximise the benefits while minimising potential risks associated with ammonia-based cleaners, maintaining cleaning efficiency.

Vinegar-based Window Cleaners

Vinegar-based window cleaners have gained popularity as an eco-friendly alternative for effective cleaning, providing a natural solution that is both safe and efficient. This type of cleaner leverages the acidic properties of vinegar to dissolve dirt and residues, making it a favoured choice for those looking to clean without chemicals while still achieving quality results and sparkling glass.

The effectiveness of vinegar-based cleaners lies in their ability to cut through grime and eliminate streaks, ensuring a crystal-clear finish. Users appreciate how simple it is to prepare these cleaners at home; a common recipe involves mixing one part vinegar with one part water in a spray bottle. Many find that using a microfibre cloth enhances the cleaning process, trapping dust and dirt rather than just pushing it around.

- For optimal results, it is recommended to clean windows on a cloudy day to prevent the solution from drying too quickly.

- Some even add a few drops of washing-up liquid to their mixture for extra cleaning power.

Those who have made the switch to vinegar-based solutions often share their satisfaction, noting improved air quality and an overall fresh feeling in their homes. With these benefits, it is easy to see why this method has gained a loyal following.

Natural/ DIY Window Cleaners

Natural or DIY window cleaners offer an affordable cleaning option that allows users to create effective cleaning solutions using household items, fostering creativity and sustainability. Common ingredients such as bicarbonate of soda, lemon juice, and cornflour can be combined to develop cleaning techniques that rival commercial products in performance while being eco-friendly and economical.

By opting for these environmentally friendly alternatives, individuals not only reduce their exposure to harsh chemicals found in many traditional products but also contribute to a greener planet. DIY window cleaners are simple to make, allowing everyone to tailor their cleaning solutions based on personal preferences and needs.

Here are some straightforward recipes:

- Basic Vinegar Solution: Mix equal parts of water and white vinegar in a spray bottle. This is great for cutting through grime.

- Lemon Power Cleaner: Combine water with the juice of one lemon and a teaspoon of cornflour for a streak-free shine.

- Essential Oil Infusion: Add a few drops of essential oils such as lavender or tea tree to your vinegar mix for a pleasant scent and added antibacterial properties.

Users can evaluate the effectiveness of these homemade solutions by comparing them directly with their shop-bought counterparts. A quick test on various window surfaces will reveal their cleaning prowess, all while being an enjoyable DIY project.

What Are The Best Window Cleaners For Different Types Of Windows?

Selecting the best window cleaners for different types of windows is essential to ensure effective cleaning and maintenance, as various glass surfaces require tailored approaches for optimal results, using the best window cleaning tools.

Whether you are dealing with standard glass windows, tinted glass, or hard-to-reach areas, understanding the specific needs of each type will help you achieve sparkling glass and enhance your home’s aesthetic appeal with the right cleaning devices.

Professional window cleaners often rely on specialised products and techniques that can significantly improve cleaning efficiency and effectiveness, leveraging modern cleaning tools.

Best Window Cleaner For Glass Windows

The best window cleaner for glass windows is often a solution that combines effective cleaning performance with ease of use, ensuring streak-free results. Popular options include commercial products designed specifically for cleaning glass surfaces, which often feature user-friendly designs that enhance their application and effectiveness in removing dirt and fingerprints, avoiding cleaning residues.

Many users rave about the effectiveness of products like the Mr. Clean Magic Eraser, known for its ability to tackle tough stains without harsh chemicals. Cleaning reviews online frequently highlight its cleaning product recommendations.

- Another standout is Windex, famed for its streak-free shine and availability in convenient spray bottles. It's often mentioned in cleaning reviews and evaluations.

- For a more eco-friendly choice, consider Method's Glass Cleaner, which utilises plant-based ingredients that users appreciate for both performance and sustainability, making it a powerful window cleaner.

These products not only streamline the cleaning process but also receive high marks in user reviews for their quick-drying capabilities and pleasant scents, making routine cleaning less of a chore. Affordable cleaning options and cleaning product evaluations often highlight their benefits.

Find out more: How To Clean Window Glass

Best Window Cleaner For Tinted Windows

For tinted windows, the best window cleaners are those formulated to clean effectively without damaging the film, ensuring a clear view and maintaining the integrity of the tint. Trusted brands, such as Vileda and Ecover, often provide specialised products that cater to the unique needs of tinted surfaces, combining gentle formulas with effective cleaning techniques.

These cleaners not only enhance the appearance of the windows but also provide a streak-free finish that is vital for optimal visibility while driving. Users often share their satisfaction with products specifically designed for tinted windows, noting how well they remove dirt and grime without leaving any harmful residues.

Here are some key points to consider when selecting these specialised cleaners:

- pH-balanced formulas help preserve the tint’s adhesive and quality.

- Apply with a soft microfibre cloth to prevent scratches.

- Avoid ammonia-based products, which can deteriorate the tint over time.

Many car enthusiasts agree that using such recommended products not only aids long-term maintenance but also enhances the overall aesthetic of their vehicles. Cleaning reviews often commend these products for their cleaning performance tests and high ratings on platforms like Amazon and Argos.

Best Window Cleaner For Mirrors

In terms of cleaning mirrors, the best window cleaners are those that offer a streak-free shine without the need for harsh chemicals, making them safe for everyday use. Many user-friendly products are designed specifically for mirrors, ensuring that users can maintain their reflective surfaces effortlessly and without damaging the glass. Cleaning product choices from brands like Astonish and Mr Muscle are popular among consumers.

To achieve the ideal cleaning experience, it’s worth considering products that boast features like a no-drip formula and easy spray application. These attributes not only make the process smoother but also help in preventing excess liquid from running down the glass, which can lead to streaks. Easy-to-use products like those from Kärcher are often recommended for this purpose.

Here are some reputable options:

- Eco-Friendly Cleaners: These cleaners are not only gentle on the environment but also ensure safety for families and pets.

- Foaming Sprays: A foaming action can better adhere to surfaces, allowing for enhanced cleaning without the mess.

- Microfibre Cloths: Pairing a great cleaner with high-quality cloths can remove dirt and grime effectively, securing that pristine finish.

By selecting the right products, maintaining your mirrors will become a straightforward and efficient task, ensuring that they continue to enhance your space.

Best Window Cleaner For Hard-to-Reach Windows

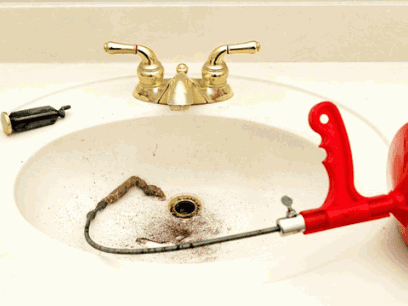

For hard-to-reach windows, the best window cleaners often incorporate portable cleaning tools that enable effective access and cleaning from challenging angles. These solutions are designed for convenience and efficiency, allowing both professional window cleaners and homeowners to achieve quality results without compromising safety.

Particularly popular among DIY enthusiasts and professionals alike are products with extendable handles and rotating heads. These features allow users to manoeuvre effortlessly around corners and tight spaces, making tedious cleaning tasks a breeze. Cleaning attachments from brands like Leifheit and Beldray are often recommended for their effectiveness.

- For instance, telescopic window cleaning poles can extend to impressive lengths, allowing one to clean high-rise buildings without the need for scaffolding.

- Innovative squeegee designs that integrate scrubbers make the process even smoother, combining scrubbing and drying in one go.

User experiences often highlight the effectiveness of these tools in maintaining sparkling clear windows, with many noting that the portability of cleaning kits reinforces their ease of use.

Practical tips include using distilled water for streak-free shine and testing new tools on less visible windows to perfect techniques before tackling more prominent displays.

What Are The Safety Measures When Using Window Cleaners?

When using window cleaners, it is vital to adhere to safety measures that protect both the user and the environment, ensuring a safe and effective cleaning experience. Wearing appropriate protective gear, such as gloves and goggles, can safeguard against potential chemical exposure while choosing eco-friendly products can minimise health risks and environmental impact.

Understanding user-friendly features of cleaning supplies can also enhance safety during use.

Proper Ventilation

Ensuring proper ventilation when using window cleaners is essential to minimise the inhalation of potentially harmful fumes and to maintain a safe indoor environment. Good airflow helps dissipate any chemical odours and reduces the risk of respiratory irritation, making it a vital component of effective cleaning techniques.

Maintaining a well-ventilated space is not just a practical consideration but also a key factor in promoting health and safety during the cleaning process. Ventilation is crucial as it allows fresh air to circulate, which helps to dilute any concentrated fumes.

Here are some practical tips to ensure good airflow:

- Open windows and doors to create cross-ventilation.

- Use fans to promote airflow, directing them towards the window to push out contaminated air.

- Consider using air purifiers equipped with HEPA filters that can help capture airborne toxins.

When choosing window cleaners, opt for products labelled as non-toxic or eco-friendly, as these typically have lower levels of harmful chemicals. It’s also a wise idea to test any new product in a small area first to gauge its impact on air quality.

Protective Gear

Wearing protective gear, such as gloves and goggles, is a crucial safety measure when using window cleaners to shield against skin and eye irritation caused by chemical exposure. This simple precaution not only safeguards health but also ensures a more comfortable cleaning experience.

To enhance safety while maintaining your cleaning routine, consider incorporating additional protective items. For instance, using a long-sleeved shirt can protect your skin from drips and splashes, while non-slip footwear ensures stability during high-altitude tasks.

When selecting such gear, keep the following tips in mind:

- Choose gloves made from materials resistant to chemicals, such as nitrile or latex.

- Select goggles that provide a secure fit and prevent any liquids from breaching the eyewear.

- Consider using a face mask if the cleaning solution has strong fumes, ensuring a comfortable atmosphere.

Paying attention to the specific cleaning products being used is essential, as some may require more robust protective measures than others.

Proper Storage Of Window Cleaners

Proper storage of window cleaners is essential to maintain their effectiveness and to ensure safety, especially in households with children or pets. Storing cleaning supplies in a cool, dry place and using child-proof containers can minimise risks and prolong the life of eco-friendly products.

Maintaining an optimal temperature range is crucial. Ideally, window cleaners should be kept between 10°C to 27°C to prevent any chemical degradation or loss of effectiveness. It's wise to check labels for specific instructions on storage.

- Always store these supplies out of reach of children, preferably in locked cupboards.

- Categorise cleaning products to avoid confusion, separating eco-friendly options from harsher chemicals.

- Consider using refillable containers to reduce waste and promote environmental consciousness.

Taking these precautions not only ensures a safer environment but also supports the longevity of the products used.

How To Make Your Own Window Cleaner?

Making your own window cleaner is an affordable option that allows you to customise your cleaning solution to meet specific needs while using common household ingredients. Many effective recipes can be created using items like vinegar, lemon juice, or bicarbonate of soda, providing a natural cleaning solution that is both cost-effective and environmentally friendly. Cleaning with vinegar is particularly highlighted by The Independent for its versatility.

Emphasising effective cleaning techniques can help ensure that your DIY cleaner delivers quality results.

Vinegar And Water Solution: A Classic Cleaning Method

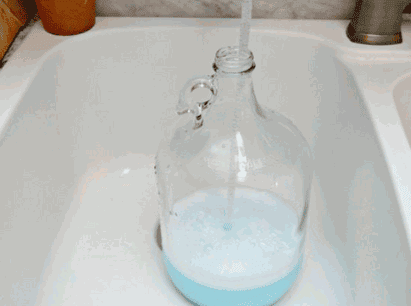

A vinegar and water solution is one of the simplest and most effective DIY window cleaners, leveraging the natural cleaning power of vinegar to dissolve dirt and grime without the need for harsh chemicals. This eco-friendly product is not only safe for the environment but also easy to make and use, ensuring that your windows shine with minimal effort. Popular brands like Method and Ecover also offer eco-friendly alternatives.

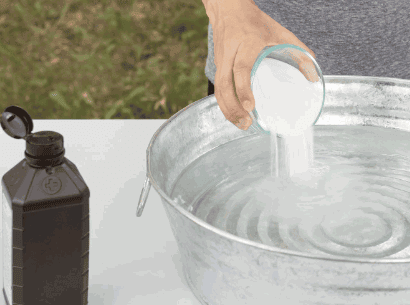

To create the perfect cleaning mixture, combine equal parts of white vinegar and water, typically one cup of each, in a spray bottle. This simple ratio makes it easy to remember and mix, providing a potent yet gentle solution.

When applying the mixture, it’s best to use a microfibre cloth or a squeegee, as these tools help minimise streaks and ensure a thorough clean without scratching the glass. For optimal results, consider cleaning your windows on a cloudy day to prevent the solution from drying too quickly, which can lead to streaking.

By following these best practices, you can enjoy sparkling windows that truly enhance the beauty of your spaces.

Lemon Juice And Water Solution: A Popular Window Cleaning Method

A lemon juice and water solution is another effective DIY window cleaner that harnesses the natural acidity of lemons to cut through grease and grime while leaving a fresh scent. This easy-to-make cleaner not only offers effective cleaning properties but also serves as a delightful aromatic addition to your cleaning routine. The Good Housekeeping Institute often recommends natural options like this.

To create this powerhouse cleaner, simply mix one part lemon juice with two parts water in a spray bottle. The citric acid in lemon juice not only helps to break down stubborn stains but also acts as a natural antibacterial agent, making this solution both safe and eco-friendly.

When applying the solution, use a microfibre cloth to achieve streak-free results. Lightly dampen the cloth with the mixture and wipe down the windows, making sure to follow a zigzag pattern to cover the surface evenly.

Here are some:

- Tips for Application:

- Apply the solution on cool surfaces to prevent rapid evaporation.

- Wipe with a clean, dry cloth afterward for a brilliant shine.

In comparison to traditional cleaning products, this lemon solution stands out for its affordability and lack of harsh chemicals, ensuring a clean environment without compromising indoor air quality. Retailers such as Amazon, Argos, and Robert Dyas often provide similar natural cleaning agents.

Baking Soda And Water Solution: A Trusted Technique For Cleaning Streak-Free

A bicarbonate of soda and water solution serves as an excellent DIY window cleaner, utilising the mild abrasive properties of bicarbonate of soda to scrub away dirt and residues without scratching the glass. This affordable cleaning option is particularly effective for tackling tough stains and can be combined with other natural ingredients for enhanced cleaning performance. Brands like Mr Muscle and Astonish offer similar effective solutions.

To prepare this cleaning mixture, simply mix three tablespoons of bicarbonate of soda with one litre of warm water in a spray bottle, creating a paste-like consistency that can be adapted based on the required cleaning strength. For added effectiveness, consider incorporating vinegar, which not only amplifies the cleaning power but also leaves windows streak-free.

When applying the solution, follow these tips to maximise results:

- Dampen a cloth or sponge with the mixture before scrubbing to ensure the bicarbonate of soda adheres properly to tougher grime.

- Use a separate microfibre cloth to wipe the surface dry, as this can significantly reduce streaking.

- For outdoor windows, clean during cooler parts of the day to prevent the solution from drying too quickly.

This versatile method is not only easy to prepare but also environmentally friendly, making it a go-to choice for households aiming for a sparkling finish without harsh chemicals. Consider tools from Kärcher and Vileda for optimal application.

Window blinds, such as Venetian blinds and roller blinds, can transform a room’s ambiance, but they often gather dust and grime over time, emphasizing the need for regular cleaning chores like vacuuming floors and dusting blinds.

Keeping them clean is not just about aesthetics; it’s essential for maintaining air quality and prolonging their lifespan.

This article explores the importance of cleaning window blinds, the consequences of neglecting them, and a variety of types available, including cellular shades and Faux Wood blinds.

You'll also find the materials needed, a straightforward step-by-step cleaning guide, and helpful cleaning tips for ongoing maintenance, like using dish soap and dishwashing liquid.

Dive in to ensure your blinds stay fresh and inviting!

Why Is It Important To Clean Window Blinds?

Cleaning window blinds is an essential household chore that not only enhances the aesthetics of your home but also contributes to a healthier indoor environment. Over time, dust, allergens, and dirt accumulate on blinds, especially in areas like Queens, which may lead to respiratory issues and reduced air quality. Regular tasks such as cleaning windows and washing laundry help keep your environment clean.

According to the Good Housekeeping Institute, regular cleaning is crucial to maintain the function and appearance of various types of blinds such as wooden blinds and fabric blinds. Additionally, a clean living space reflects well on your personal hygiene and creates a welcoming atmosphere for guests.

What Happens If You Don't Clean Window Blinds?

Neglecting to clean window blinds can lead to the accumulation of dirt and allergens, which can pose health risks for individuals with allergies or respiratory issues, complicating their everyday lives and potentially triggering serious health conditions that require medical attention and ongoing management.

For example, those with asthma may find their symptoms exacerbated by the presence of dust mites and mould spores, both of which thrive in dirty blinds. This makes it essential for everyone, especially allergy sufferers, to maintain a regular cleaning schedule.

Here are some common cleaning methods that can effectively remove stubborn stains and ensure a healthier living environment:

- Dusting with a microfibre cloth to capture particles instead of spreading them around.

- Using a vacuum attachment to reach the intricacies of the blinds easily.

- Employing a mixture of warm water and mild detergent for deeper stains when necessary.

Consistent cleaning not only keeps the blinds looking great but also minimises allergens in the air, reinforcing the importance of employing proper cleaning techniques.

Types Of Window Blinds

There are various types of window blinds available, each with its unique characteristics, including:

- vertical blinds

- horizontal blinds

- wooden blinds

- fabric blinds

These require tailored cleaning techniques and specific cleaning products to maintain their appearance and functionality.

Vertical Blinds

Vertical blinds, commonly used for larger windows and sliding doors, require specific cleaning products and techniques to effectively remove dust and dirt, ensuring they maintain their aesthetic appeal and functional integrity over time. Brands like Hillarys and Greenworks offer solutions for these tasks.

In terms of cleaning vertical blinds, choosing the right products is essential. It is advisable to use mild detergents mixed with warm water, along with soft cloths or sponges, to avoid damaging the material.

- Routine maintenance is key; dusting should occur every few weeks, while deeper cleaning might be needed every few months, depending on environmental factors.

- For a quick dust removal, a microfibre duster or a vacuum with a brush attachment can be effective.

Consider using specialised blind cleaning solutions which can help eliminate stubborn grime without harming the texture of the blinds.

Horizontal Blinds

Horizontal blinds, a popular choice for many households, allow for easy dusting and can be maintained with simple cleaning techniques that ensure they remain functional and aesthetically pleasing. By implementing these techniques, one can prolong the lifespan of the blinds, reduce allergens, and keep their living space looking fresh and inviting. Consider using products like Swiffer and Dawn Powerwash Spray for effective cleaning.

To start, gather the necessary materials:

- Microfibre cloths

- Wood or vinyl cleaner

- Warm, soapy water

- A soft brush or vacuum with a brush attachment

Before cleaning, it is advisable to tilt the blinds open, making it easier to reach each slat. Gently wipe down each slat with a microfibre cloth dampened in the soapy water solution, ensuring you catch any dust and debris that may have accumulated.

For stubborn stains, opt for a specialised cleaner suited to the material of the blinds. To prevent future build-up, consider a quick dusting session every week or two.

These simple yet effective habits not only maintain the appearance of horizontal blinds but also keep the environment healthier for you and your family.

Wooden Blinds

Wooden blinds require a delicate cleaning process to preserve their finish while effectively removing dust and allergens.

To maintain their beauty and functionality, it is crucial to use appropriate cleaning methods and products tailored specifically for wood blinds. Unlike synthetic materials, wood can be sensitive to harsh chemicals and excessive moisture, so using gentle products like those recommended by Architectural Digest is advised.

Start by dusting the blinds with a microfiber cloth or a duster, which will effectively capture dust without scratching the surface. For a deeper clean, use a solution of mild washing-up liquid and warm water, applying it sparingly with a soft cloth. Remember to avoid soaking the wood, as excess water can warp or damage it.

- Use furniture polish occasionally for added shine and protection.

- Avoid commercial cleaners containing ammonia or bleach.

Regular maintenance not only enhances their appearance but also prolongs their lifespan, ensuring your investment remains worthwhile.

Fabric Blinds

Fabric blinds can attract dust and stubborn stains, making regular cleaning essential to maintaining their appearance and ensuring a lasting, fresh look that enhances your home’s aesthetic.

To effectively care for these window treatments, consider using a combination of gentle cleaning solutions and regular maintenance routines, including employing techniques recommended by experts like Yvonne Keal from the Good Housekeeping Institute.

- Begin with a soft brush attachment on a vacuum cleaner or a microfibre cloth to remove loose dust particles.

- For stubborn stains, a mixture of mild soap and lukewarm water can be applied with a soft cloth; always test a small area first to prevent damage.

- When using any cleaning solution, it's advisable to follow the manufacturer’s guidelines for the fabric type.

It’s beneficial to use protective measures, such as avoiding placing blinds in direct sunlight for long periods to prevent fading and discolouration. In doing so, one can prolong the lifespan of their fabric blinds while keeping them looking pristine, as recommended by experts from Hofstra University.

Materials Needed For Cleaning Window Blinds

To effectively clean window blinds, you will need essential materials such as a vacuum cleaner, microfibre cloths, and cleaning solutions like vinegar and washing-up liquid, which provide a comprehensive cleaning approach.

Take a look: What Is The Best Window Cleaner

Vacuum Cleaner

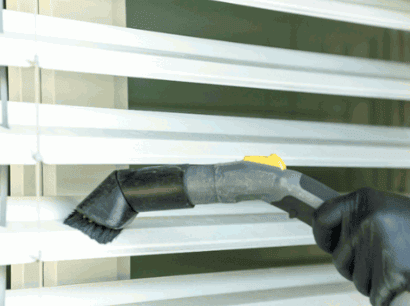

A vacuum cleaner is an effective tool for quickly removing dust from blinds, especially when fitted with a brush attachment, making it a preferred choice for cleaning methods.

Using a vacuum cleaner not only saves time but also enhances efficiency in maintaining the cleanliness of your blinds.

Incorporating the right vacuum attachment can significantly impact results. Here are some tips for choosing the best option:

- Choose a brush attachment specifically designed for delicate surfaces. This helps in preventing damage while ensuring a thorough cleaning.

- Consider a handheld vacuum for tighter spaces, allowing you to reach those tricky angles with ease.

- Look for adjustable suction settings to cater to various materials and dust levels.

By considering these factors, the efficiency of your cleaning routine will be greatly enhanced, providing a fresh and dust-free environment.

Microfiber Cloth

Microfibre cloths are ideal for dusting and wiping down window blinds due to their ability to trap dust and allergens effectively without scratching surfaces.

This unique material consists of tiny fibres that create a static charge, helping to lift dirt and debris away rather than spreading it around. When using microfibre cloths for cleaning blinds, it is beneficial to adopt a few simple application methods:

- First, gently wrap the cloth around your fingers to create a soft tool that fits snugly into the slats, allowing for efficient cleaning.

- Next, lightly dampen the cloth with a cleaning solution to enhance its dust-attracting properties, preventing finer particles from drifting back into the air.

- For optimal results, ensure cleaning from top to bottom, as this strategy minimises the redistribution of dust.

Maintenance of the microfibre cloths is equally crucial. Wash them in cold water, avoiding fabric conditioners as they can diminish the cloth's effectiveness. Regular cleaning will ensure they maintain their superior dust-trapping capabilities, making them a fantastic and eco-friendly choice for household upkeep.

Vinegar Solution

A vinegar solution is an excellent natural cleaner for window blinds, effectively cutting through grime and leaving surfaces streak-free. Not only does this affordable cleaning method minimise the need for harsh chemicals, but it also ensures a safer environment for families and pets alike.

To create the perfect vinegar solution, combine equal parts of white vinegar and water in a spray bottle. This simple mixture can tackle various types of blinds, including fabric, aluminium, and vinyl, making it versatile.

- Gently dust the blinds using a microfibre cloth to remove loose dirt.

- Spray the vinegar solution lightly on the blinds.

- Wipe down each slat with a clean cloth, focusing on any stubborn spots.

The natural acidity of vinegar not only cleans but also acts as a disinfectant, enhancing the overall cleanliness of your living space.

Dish Soap Solution

A washing-up liquid solution can effectively target stubborn stains and provide a thorough cleaning for various types of window blinds.

Creating a washing-up liquid solution is quite simple and can lead to remarkable results. Begin by mixing a few drops of a gentle washing-up liquid with warm water in a bucket. The warm water helps to dissolve grease and dirt more efficiently, making it easier to lift stubborn stains from the blinds.

In terms of application, it’s advisable to use a soft cloth or sponge dipped in the soapy solution, ensuring it’s not overly saturated to prevent drippage. Gently wipe each slat, paying extra attention to any spots that appear to be particularly dirty.

- For tough grime, allow the solution to sit for a minute before scrubbing.

- Always test a small hidden area first to ensure the blinds' material is compatible with the solution.

After cleaning, wipe with a damp cloth to remove any leftover soap and let the blinds air dry for a sparkling finish.

Step-by-Step Guide For Cleaning Window Blinds

This step-by-step guide will help you through the entire cleaning process for window blinds, ensuring that you achieve optimal cleanliness while effectively managing your cleaning tasks.

Dusting The Blinds

The first step in cleaning window blinds is dusting, which can be effectively done using microfiber cloths to capture dust and allergens.

To achieve optimal results, it's essential to approach the task methodically. Begin by selecting a clean microfibre cloth that is slightly damp to enhance its dust-attracting capabilities. Hold the slats of the blinds firmly with one hand while using the cloth in a gentle, wiping motion with the other. This technique ensures that any accumulated dirt is effectively caught and removed without leaving behind residue.

- Tips for thorough cleaning from Yvonne Keal at Hillarys:

- Start from the top and work your way down to avoid resettling dust on already cleaned areas.

- For horizontal blinds, wipe each slat individually, repositioning the cloth to cover all surfaces.

- Use a ladder or step stool if needed to reach higher blinds safely.

Following these guidelines will help keep window blinds looking pristine while minimising allergens in your home. Consider using a Swiffer for quick touch-ups.

Vacuuming The Blinds With Tools

After dusting, vacuuming the blinds with a vacuum cleaner will remove any remaining dust and debris, providing a thorough cleaning.

Utilising a vacuum cleaner not only enhances the aesthetic of your blinds but also contributes to a healthier living environment. Employing the right attachments is crucial; consider using a crevice tool to effectively reach into corners and crevices where dust tends to accumulate.

Here are some techniques to ensure a meticulous cleaning process:

- Turn the blinds: Angle them fully open to allow for easy access.

- Use the right suction: Adjust the settings on your vacuum to avoid damaging delicate materials.

- Ventilate: Open nearby windows to circulate air, making it easier to see dust floating away.

Regular maintenance, including vacuuming, will prolong the life of the blinds and keep them looking as good as new.

Wiping Down With Vinegar Solution

Using a vinegar solution is a crucial step in the cleaning process, as it helps dissolve grime and leaves the blinds sparkling clean, valuable for cleaning Venetian blinds, Faux Wood blinds, or Pleated blinds, enabling homeowners to maintain the fresh and inviting indoor environment without relying on harsh chemicals.

To properly apply the vinegar solution to the blinds, mix equal parts water and white vinegar in a spray bottle. Lightly mist the blinds, focusing on the areas with more buildup. Use a soft cloth or a microfibre duster to gently wipe each slat, following the direction of the blinds. The vinegar solution not only cleans but also eliminates odours, leaving your home smelling fresh.

After cleaning, it’s important to rinse or dry the blinds to prevent any vinegar smell from lingering. Here are some tips from Jodhaira at Hofstra University:

- Wipe with a damp cloth to remove any excess vinegar.

- Allow the blinds to air dry by leaving them open.

- If necessary, use a clean, dry cloth to speed up the drying process.

By following these steps, you can enjoy the multitude of benefits this natural cleaner offers while ensuring your blinds regain their pristine condition.

Deep Cleaning With Dish Soap Solution

For a thorough clean, especially for stubborn stains, a washing-up liquid solution can be applied to deep clean the blinds.

This simple yet effective method not only revitalises the appearance of blinds but also aids in maintaining their longevity. To begin, prepare a solution by mixing warm water with a few drops of your favourite washing-up liquid or Dawn Powerwash Spray. The warm water helps to loosen any grime, while the liquid cuts through grease.

- Soaking Method: For more stubborn dirt, use a microfibre cloth soaked in the mixture.

- Gently wipe the surfaces, allowing the solution to penetrate the stains.

- After soaking for several minutes, rinse with clean water using another cloth.

For lighter cleaning needs, a simple rinse with the soap solution followed by thorough drying can work wonders. Always ensure the blinds are completely dry to prevent any moisture damage.

Tips For Maintaining Clean Window Blinds

Maintaining clean window blinds is easier with consistent cleaning tips and a routine that incorporates regular dusting and quick cleaning methods. Consider products like Greenworks or Dishwashing liquid for effective maintenance.

Cleaning windows goes beyond mere aesthetics; it enhances your home's appearance and prolongs the life of your window frames.

Whether you're looking to banish streaks or maintain clarity, understanding the right tools and techniques is essential.

This guide covers the importance of window cleaning, the best tools to use, and step-by-step instructions for various window types, ensuring you avoid common cleaning mistakes.

Find window cleaning tips for maintaining that sparkling finish, ensuring your windows stay pristine all year round.

Why Is It Important To Clean Window Glass?

Cleaning window glass is essential not only for aesthetic reasons but also for improving natural light, enhancing your home's ambience, and extending the lifespan of your windows. Dirty windows can accumulate grime, dust, and fingerprints, which can obstruct your view and negatively impact the overall appearance of your home.

Regular cleaning helps maintain window integrity, prevents deterioration, and ensures proper functionality of window treatments. Furthermore, using effective cleaners like distilled vinegar or a baking soda mixture can promote safe cleaning practices, making it a crucial part of home cleaning routines.

Learn more: How To Clean Window Blinds

What Tools Do You Need For Cleaning Window Glass?

To effectively clean window glass, having the right tools is crucial. Essential tools include a reliable glass cleaner, which can be a commercial product or a homemade solution using distilled vinegar, baking soda, or lemon juice, and cleaning equipment like a squeegee for a streak-free finish.

Additionally, a microfibre cloth is essential for dust removal and polishing glass surfaces without leaving fluff behind, perfect for achieving window shine.

What Are The Different Types Of Window Glass Cleaners?

Regarding cleaning window glass, several types of cleaners are available, each with its unique benefits. Commercial glass cleaners are widely used for their convenience, but many homeowners opt for natural alternatives like vinegar cleaner or rubbing alcohol to achieve a streak-free finish while ensuring safe cleaning practices. These DIY cleaners, made from household items, are not only cost-effective but also environmentally friendly, providing effective cleaning solutions without harsh chemicals, such as Invisible Glass Cleaner or E-Cloth Window Cleaning Kit.

In comparing the two approaches, it's essential to consider factors such as effectiveness and safety.

While commercial products often contain powerful solvents and fragrances that can swiftly tackle tough grime, they may irritate sensitive skin or respiratory systems. On the other hand, homemade cleaners typically utilise ingredients like vinegar, bicarbonate of soda, and water, which are generally safe and non-toxic.

- Pros of Commercial Cleaners:

- Quick and efficient

- Readily available

- Designed specifically for tough stains

- Cons of Commercial Cleaners:

- Contains harsh chemicals

- Can cause allergies or irritations

- More expensive long-term

- Pros of Homemade Cleaners:

- Eco-friendly

- Inexpensive and effective

- Customise your fragrance

- Cons of Homemade Cleaners:

- It may require more elbow grease

- Not always effective on heavily soiled surfaces

Ultimately, the choice between commercial and homemade cleaners depends on individual preferences, cleaning needs, and whether a cleaning expert's advice is followed.

What Are The Essential Cleaning Tools?

Essential cleaning tools for window maintenance include a high-quality squeegee, which is crucial for achieving a streak-free finish, and microfibre cloths that effectively remove dust and fingerprints from glass surfaces. Having a variety of cleaning supplies on hand, such as vinegar solution or baking soda paste, gives you the power to you to tackle different cleaning tasks efficiently.

To ensure a comprehensive approach, consider these additional essential tools:

- Bucket: Essential for holding cleaning solutions, a sturdy bucket aids in mixing and transporting your cleaning supplies, preventing spills.

- Scrubber: A soft-bristle scrubber helps to loosen dirt and grime before the squeegee takes over, ensuring a more thorough clean.

- Extendable Pole: For hard-to-reach windows, an extendable pole with an attachment can save considerable time and effort.

- Window Cleaning Solution: A dedicated solution, either commercial or homemade, ensures the best results as it cuts through grease without leaving residue.

Incorporating these tools into your routine not only promotes a polished appearance but also enhances the lifespan of the glass, making each cleaning session more effective. By utilising these essential tools, the quest for spotless windows becomes a manageable task that aligns with advice from the Good Housekeeping Institute.

How To Prepare For Cleaning Window Glass?

Preparing to clean window glass involves a systematic approach to ensure efficiency and optimal results. Start by gathering all necessary cleaning supplies and tools, including a squeegee, microfibre cloths, and your chosen cleaning solution, whether it is a vinegar mixture, soapy solution, or commercial glass cleaner.

Additionally, remove any items obstructing access to the windows, such as window screens or furniture, to facilitate a thorough cleaning process that adheres to safe cleaning practices.

What Are The Safety Measures To Take?

Safety measures are crucial when cleaning window glass to prevent accidents and ensure effective cleaning. Always ensure that you have a firm footing, use a stable ladder or platform if cleaning high windows, and avoid using harsh chemicals that could harm your health or the environment. Opt for a vinegar cleaner or other safe cleaning solutions made from household items like cornstarch, and wear gloves if necessary to protect your skin.

Plus a sturdy ladder, consider using a spotter to hold the base or to provide additional support, which can significantly enhance window cleaning safety. Always check the ladder's condition before use, ensuring that it is free from any defects.

Regarding chemical handling, prioritize those that are eco-friendly and non-toxic; this not only protects your wellbeing but also maintains a safer environment for all.

- Wear protective eyewear when spraying any cleaning solution.

- Ensure adequate ventilation if using any chemical products.

- Store all cleaning supplies safely, out of reach of children and pets.

Physical safety is just as paramount; remember to lift heavy cleaning tools with your legs and not your back. By following these basic precautions and adopting safer cleaning solutions, window maintenance can become a much more enjoyable and hazard-free task.

What Is The Best Time To Clean Window Glass?

Utilising advice from experts can enhance your cleaning strategy.

The best time to clean window glass is typically on a cloudy day, as this prevents direct sunlight from causing streaks and allows for better visibility of smudges and dirt. Early morning or late afternoon can also be ideal, as temperatures are cooler, reducing the chances of cleaning solutions drying too quickly during the cleaning process. This timing aligns with the effective cleaning methods recommended by cleaning experts.

Opting for these specific conditions can significantly improve the overall outcome of the task. When window cleaning occurs on a cloudy day, the absence of harsh sunlight makes smudges and other imperfections more easily noticeable, thereby enabling a thorough and effective cleaning. During early morning hours or late afternoons, the mild temperatures not only enhance the performance of cleaning products but also safeguard the surfaces from extreme temperature fluctuations that could affect the integrity of the glass.

- Humidity levels also play a crucial role; moderate humidity can help maintain wetness, ensuring that the cleaning solution works its magic.

- Avoiding windy conditions prevents dust and debris from settling on freshly cleaned windows.

By strategically timing the cleaning process, one can ensure that every window shines beautifully, providing a clearer view and enhancing kerb appeal.

How To Clean Window Glass Step-by-Step?

Cleaning window glass step-by-step ensures thoroughness and a streak-free finish, making the process efficient and effective.

- Start by removing any dirt or debris from the window panes using a dry microfibre cloth.

- Prepare a cleaning solution, which could be a vinegar mixture or a soapy solution.

- Apply the cleaner to the glass.

- Scrub gently with a sponge or cloth.

- Rinse thoroughly with clean water.

- Finish by drying the glass with a squeegee or soft cloth.

Step 1: Remove Any Dirt Or Debris From The Window

The first step in cleaning window glass is to remove any dirt or debris accumulated on the window panes. Using a dry microfibre cloth or a soft brush, gently wipe away loose dust, cobwebs, and other debris to prepare the surface for cleaning.

Not only does this preliminary action ensure a clearer view, but it also plays a crucial role in preventing scratches during the actual cleaning process. Neglecting to remove this surface debris may lead to unwanted scratches, compromising the integrity of the glass.

For effective dirt removal, it is recommended to:

- Start from the top of the window and work your way down.

- Use a soft brush to dislodge stubborn debris without scratching.

- Ensure the cloth used is clean and dry to avoid applying any additional dirt.

This attention to detail sets the stage for an efficient and thorough cleaning, maintaining the clarity and aesthetic of the glass.

Step 2: Prepare The Cleaning Solution Using DIY And Natural Cleaning Methods

Preparing the cleaning solution is crucial for achieving a streak-free finish on window glass, whether you opt for a DIY cleaner or commercial options.

Among the various options, many prefer making a vinegar-based cleaning solution, which not only cleans but also disinfects effectively. To create this mixture, simply combine equal parts distilled vinegar and warm water in a spray bottle, providing an economical approach to cleanliness. If they are facing particularly stubborn grime, a soap solution consisting of mild detergent diluted in warm water can be exceptionally beneficial. For a more refreshing alternative, mixing two tablespoons of lemon juice with a litre of water offers both cleaning properties and a pleasant scent.

- Vinegar Mixture: 240 ml distilled vinegar + 240 ml warm water

- Soap Solution: 30 ml mild detergent + 1 litre warm water

- Lemon Juice Cleaner: 30 ml lemon juice + 1 litre water

By using these natural ingredients, not only will they ensure a sparkling clean finish, but they will also embrace eco-friendly choices in their cleaning habits, promoting window care with minimal environmental impact.

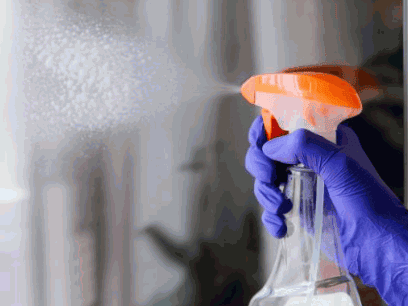

Step 3: Apply The Cleaning Solution To The Glass Including Window Tracks

Applying the cleaning solution to the glass is key to achieving a thorough cleaning. Use a spray bottle to evenly distribute your chosen cleaning solution over the window surface, focusing on areas with heavy grime or fingerprints for optimal cleaning.

To ensure the best results, it’s essential to maintain a systematic approach while applying the cleaning solution. Begin by thoroughly shaking the spray bottle to mix the solution, allowing for maximum efficacy. Next, hold the bottle approximately 30 centimetres away from the glass surface. This distance helps in achieving an

- even distribution

- preventing over-saturation

- reducing drips

which can often lead to streaks.

Consider the type of product you are using. High-quality glass cleaners can significantly enhance your results and protect against future smudges. Ensure coverage extends to the edges to avoid any build-up of dirt in commonly neglected areas. Always wipe in a circular motion using a microfibre cloth, which is gentle on the glass yet effective in lifting stubborn residues.

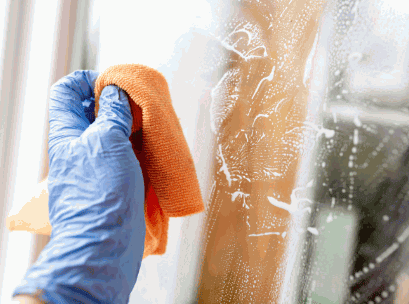

Step 4: Scrub The Glass With A Sponge Or Soft Cloth For Effective Residue Removal

Once the cleaning solution is applied, the next step is to scrub the glass gently with a sponge or soft cloth. Using a microfibre cloth is highly recommended as it effectively lifts dirt without scratching the glass surface. Cleaning windows can be a satisfying task when approached with the right techniques, ensuring a streak-free finish that enhances visibility and aesthetics.

When scraping away grime, it’s essential to maintain gentle pressure and utilise circular motions. This method not only minimises streaks but also ensures comprehensive coverage. To tackle stubborn spots, consider soaking a corner of your cloth in the cleaning solution and allowing it to rest on the blemish for a minute before scrubbing. This extra dwell time helps to break down tough residues, making them easier to remove.

- Utilise a squeegee for larger surfaces to avoid drips and enhance window polishing.

- For tricky areas, a soft-bristled brush can be very effective.

- Always wring out excess liquid from your cleaning cloth to prevent sloppy results.

- Consider using Casabella Microfiber Glass Cloths for an impeccable finish.

Incorporating these techniques will not only simplify the job but also ensure that the glass is left sparkling clean, inviting more natural light into your space.

Step 5: Rinse The Glass With Clean Hot Water

Rinsing the glass with clean hot water is vital to ensure all cleaning solution residues are removed and to enhance the effectiveness of fingerprint cleaner.

To achieve a truly spotless finish, it is crucial to follow up your initial cleaning with a thorough rinse. Begin by filling a bucket or bowl with fresh, clean water, ideally using distilled water to prevent any mineral deposits from forming on the surface.

Using a clean sponge or cloth dampened with this water, gently wipe down the windows once more. This method not only helps in eliminating any remaining soap or vinegar residue left after scrubbing but also minimises streaking.

- Avoid rinsing with tap water when possible; minerals can lead to unsightly spots.

- For optimal results, use a soft squeegee after rinsing to remove excess water.

- Ensure the drying cloth is lint-free to prevent any residual fibres from clinging to the glass.

By taking these steps, you ensure a gleaming, streak-free finish that enhances the clarity and brightness of your windows.

Step 6: Dry The Glass With A Squeegee Or Soft Cloth And Essential Oils

The final step in the cleaning process is to dry the glass using a squeegee or a soft cloth, which is essential for achieving a streak-free finish. Start at the top corner and pull the squeegee downwards in a straight line, wiping the blade with a cloth after each pass to ensure optimal results.

To amplify the effectiveness of drying glass surfaces, consider using essential oils for a pleasant scent and follow a few best practices.

- First, ensure the glass is clean and free from loose debris, as this can lead to unsightly scratches.

- Second, consider using a high-quality squeegee that fits comfortably in your hand. A rubber blade will glide effortlessly and remove water quickly.

- Those using a cloth should opt for microfiber to trap grime and absorb moisture without leaving lint behind.

Work in sections and dry promptly to prevent water spots from forming. By following these guidelines, not only will the windows sparkle, but you'll also avoid common pitfalls that can undermine your hard work.

How To Clean Different Types Of Window Glass And Maintain Window Care?

Different types of window glass require tailored cleaning methods to ensure optimal results and maintain their integrity. For instance, tinted glass may need gentler cleaning solutions, while frosted glass can accumulate debris more quickly and require more frequent maintenance.

Understanding the distinct characteristics of each type of glass is essential for effective cleaning practices, as recommended by the Good Housekeeping Institute.

Tinted Glass

Cleaning tinted glass requires special attention to preserve its colour and integrity. Opt for a mild cleaning solution, such as a vinegar mixture, and avoid harsh chemicals that could damage the tint. Always use a soft cloth or sponge to scrub, ensuring you apply gentle pressure to prevent scratches.

Regarding maintaining the clarity and appearance of tinted glass, employing a few key strategies can make all the difference. Users should remember that proper care is essential not only for aesthetic reasons but also to prolong the life of the tinting material.

Here are some best practices, suggested by experts:

- Choose products specifically designed for tinted windows, as they often contain gentle ingredients that won't harm the film.

- Avoid using abrasive cleaners or scrubbers, as these can lead to permanent scratches and reduce the film's effectiveness.

- It is advisable to clean the glass during cooler parts of the day to prevent the cleaning solution from drying too quickly, which can leave streaks.

- Consider applying a protective coating formulated for tinted surfaces after cleaning to help repel dirt and grime.

By following these guidelines, individuals can ensure their tinted glass remains not only beautiful but also functional for years to come.

Frosted Glass Cleaning Hacks

Frosted glass can trap more dirt and fingerprints than clear glass, necessitating more frequent cleaning to maintain its appearance. Use a vinegar cleaner for effective residue removal and apply using a soft cloth to ensure a gentle touch that won't scratch the surface.

One of the specific challenges associated with cleaning frosted glass surfaces is their textured finish, which can accumulate grime in uneven pockets, making them difficult to clean thoroughly. To tackle these challenges, consider implementing a few effective strategies:

- Regular Maintenance: Schedule frequent cleanings to prevent major build-up.

- Use the Right Tools: A microfiber cloth or sponge works better than rough fabrics.

- Opt for a Dual Action Cleanser: Pair vinegar with warm water for additional effectiveness.

By incorporating these tips, one can ensure that frosted glass remains in pristine condition while avoiding issues common in cleaning home appliances.

Stained Glass

Cleaning stained glass requires a delicate approach to avoid damaging the artwork while ensuring cleanliness. Use a soft, damp cloth with a gentle cleaning solution such as distilled water mixed with a bit of mild soap to effectively remove grime without harming the glass.

Stained glass, renowned for its breathtaking artistry, also demands careful consideration during maintenance to preserve its beauty and integrity. It is essential to avoid abrasive cleaners or scrubbing brushes that could scratch the surface. Instead, the use of non-toxic solutions or a DIY cleaner is highly recommended for optimal care.

- Always test any cleaning solution on a small, inconspicuous area before applying it to the entire piece.

- Consider using a solution that specifically mentions its compatibility with stained glass.

- Regular dusting with a soft feather duster can help reduce the build-up of grime, making thorough cleaning easier.

Routine inspections can help spot potential issues such as cracked lead or loose glass, which may require professional attention. By adopting these practices, one can maintain the splendour of stained glass for years to come.

Tempered Glass

Toughened glass is generally more durable than standard glass, but it still requires proper cleaning to maintain its clarity. Using an effective cleaner like a vinegar mixture, scrub gently with a microfibre cloth, such as those found in a Casabella Microfiber Glass Cloths set to avoid scratches, ensuring that no residue remains after cleaning.

To achieve pristine results, consider incorporating the following effective cleaning methods tailored specifically for this resilient material:

- Prepare a solution: Mix equal parts white vinegar and water in a spray bottle for a natural yet potent cleaner that effectively cuts through grime.

- Choose the right tools: Opt for soft sponges or lint-free cloths, as these materials will not leave scratches or lint behind, maintaining that clear and bright appearance.

- Spot test: Always test your cleaning solution on a small, inconspicuous area first to ensure compatibility with the glass surface.

- Dry properly: After cleaning, dry the glass with a squeegee or a clean, dry cloth to prevent streaks and ensure no moisture lingers on the surface.

Incorporating these methods not only enhances the durability of toughened glass but also extends its lifespan, making maintenance a simple yet rewarding task.

Double-Pane Glass

Cleaning double-glazed glass presents unique challenges due to the sealed nature of the units. It’s essential to clean the exterior surface thoroughly and, if accessible, the interior using a mild cleaning solution like a window cleaner to prevent moisture build-up between the panes.

When dealing with moisture trapped between the layers, it’s crucial to understand that traditional cleaning methods may not suffice. If condensation appears, the integrity of the seal might be compromised, allowing air and moisture to linger.

In such cases, seeking professional intervention is often the best course of action to ensure that the longevity of the window is maintained. Regular maintenance not only enhances the aesthetic appeal of your home but also prevents potential damage down the line. Here are a few strategies:

- Use a vacuum cleaner with a small attachment to remove any dust from the edges.

- Consider desiccants if advised by professionals to absorb moisture.

- In severe cases, window replacement may be necessary.

How To Maintain Clean Window Glass?

Maintaining clean window glass involves a combination of regular cleaning and proper care to keep windows in excellent condition. Frequent cleaning helps to prevent the build-up of grime and dirt while using safe cleaning products like homemade vinegar or bicarbonate of soda solutions enhances long-term window maintenance.

Establishing a cleaning schedule ensures windows stay clear all year round.

Regularly Clean Windows

Regularly cleaning windows is essential to preserving their clarity and extending their lifespan. Establishing a cleaning schedule, ideally every month or seasonally helps prevent dirt from accumulating and makes cleaning easier in the long run.

When considering window maintenance, it's important to realise that neglected windows can develop long-term damage, such as etched glass or stubborn stains, which become increasingly difficult and costly to remove.

Incorporating a few straightforward practices into your routine can significantly elevate the overall appearance of your home. Here are some benefits of regular window cleaning:

- Clarity: Clean windows provide a clear view and allow more natural light into your space.

- Longevity: Keeping windows clean helps to extend their lifespan by preventing damage.

- Cost-effectiveness: Regular maintenance reduces the chance of requiring professional services for significant repairs.

Ultimately, by prioritising this simple maintenance task, you facilitate easier future cleanings and enhance the overall aesthetic of your home.

Use Protective Coatings

Using protective coatings on window glass can significantly reduce the accumulation of dirt and grime, making maintenance easier. These coatings can enhance the window's resistance to weather effects and help maintain its clarity, much like using an Invisible Glass Cleaner for longer periods.

Several types of protective coatings are available that cater to different needs and preferences.

- Hydrophobic coatings offer water-repellent properties, causing rainwater to bead up and roll off, taking dirt along with it.

- Low-E glass coatings reflect infrared light, improving energy efficiency while protecting against UV rays that may fade interiors.

- Anti-graffiti coatings make it easier to remove stubborn stains and graffiti without damaging the glass.

- Tinted films provide added privacy and can reduce glare, making indoor spaces more comfortable.

By incorporating these specialised coatings, property owners can not only preserve the aesthetic appeal of their windows but also minimise the frequency of cleaning, saving both time and effort.

Clean Windows In The Correct Order

Cleaning windows in the correct order is essential for achieving optimal results without missing any spots. Start with the exterior sides of the windows, then proceed to the interior, ensuring a systematic approach that maximises cleaning efficiency.

To maintain clarity and shine, it’s crucial to use the right tools and products. First, gather all necessary supplies including a glass cleaner, microfibre cloths, a squeegee, and a bucket of warm, soapy water. This preparation not only saves time but also enhances the final outcome.

- Begin by removing dust and debris from the window frame and sill.

- Next, apply the cleaner in a zig-zag pattern to ensure even distribution.

- Use the squeegee from top to bottom, wiping the blade with a clean cloth after each pass.

By adhering to this sequence, individuals can achieve streak-free and spotless windows while minimising the risk of having to redo any sections.

Avoid Harsh Chemicals

Avoiding harsh chemicals when cleaning windows is crucial for both your health and the longevity of your windows. Opt instead for safe cleaning solutions, such as vinegar, bicarbonate of soda, or commercially available products free from harmful substances.

Using natural cleaning products not only protects the environment but also ensures that your living space remains free from toxic residues. Many people overlook the potential harm that traditional cleaners can cause, not just to the surfaces they treat, but also to the quality of indoor air. Embracing alternative cleaning options can significantly reduce exposure to allergens and irritants.

- Consider mixing equal parts of water and vinegar for an effective non-toxic cleaner, as recommended by the Good Housekeeping Institute.

- Bicarbonate of soda acts as a gentle abrasive, perfect for removing stubborn stains.

- Look for eco-friendly brands that prioritise sustainability in their formulas, such as Invisible Glass Cleaner.

By making these small changes in cleaning habits, one can ensure that both the windows and health are well cared for.

Inspect For Any Damage

Regularly inspecting windows for any signs of damage, perhaps consulting experts like Cloudy2Clear for guidance, is essential for effective maintenance and prevention of future issues. Look for cracks, chips, or any leaks in the seals, as these can affect both the performance and appearance of the windows.

When undertaking this critical task, homeowners should keep an eye out for several key indicators that can signal underlying problems. Areas to check include:

- Physical Damage: Look closely for any visible cracks or chips that could lead to further deterioration.

- Seal Integrity: Ensure that the seals around windows are intact, as compromised seals can lead to draughts and energy loss.

- Moisture Accumulation: Regularly inspect for condensation between panes, as this can indicate a seal failure.

- Operating Mechanism: Verify that windows open and close smoothly without any sticking or resistance.

Addressing these issues promptly not only enhances the durability of windows but also improves energy efficiency. Consider simple cleaning tips, such as using a soft cloth and gentle window cleaner, to maintain both their clarity and functionality.

Are you looking to enhance your outdoor space with stylish, durable furniture? Resin wicker patio furniture might be just what you need.

This versatile option combines the beauty of traditional wicker with modern materials, offering a range of benefits that make it perfect for any setting.

We will explore what resin wicker is made of, its advantages, how it compares to other materials and tips for caring for it.

Plus, discover the various styles and reputable brands that can transform your patio into a cozy oasis.

Get ready to elevate your outdoor experience!

What Is Resin Wicker Patio Furniture?

Resin wicker garden furniture is a popular choice for creating stylish and functional outdoor living spaces, combining aesthetic appeal with durability. Made predominantly from synthetic rattan, this type of furniture is designed to withstand the elements while maintaining its charm, making it ideal for gardens, patios, and bistro sets.

Brands like Primrose and Leisuretouch-Rattan offer a wide variety of options, ensuring that homeowners can find the perfect pieces to enhance their outdoor areas. Resin wicker furniture not only provides comfort but also complements a range of garden styles.

What Is Resin Wicker Made Of?

Resin wicker is primarily made from synthetic materials such as High-Density Polyethylene (HDPE) and PVC, which are engineered to mimic the appearance of natural wicker while offering enhanced durability and weather resistance.

These materials not only provide a stunning aesthetic that can complement any outdoor setting, but they also bring numerous advantages over traditional wicker.

For instance, resin wicker is resistant to fading, cracking, and peeling, meaning it can withstand exposure to harsh sunlight and inclement weather without losing its charm. Unlike natural wicker, which requires extensive maintenance including regular cleaning and treatment to prevent deterioration, the synthetic variants require only minimal care, often just a quick wipe down to maintain their beauty.

This ease of maintenance ensures that the garden furniture remains in top condition, allowing homeowners to enjoy their outdoor spaces without the hassle that comes with upkeep.

Learn more: Can You Paint Resin Patio Furniture

What Are The Benefits Of Resin Wicker Patio Furniture?

Resin wicker patio furniture offers numerous benefits that make it an ideal choice for outdoor living spaces, including durability, weather resistance, low maintenance, lightweight design, and versatile aesthetics that cater to various styles and preferences.

Durable And Long-lasting

One of the standout features of resin wicker patio furniture is its durability, crafted to withstand various environmental conditions without compromising its structural integrity or aesthetic appeal. This exceptional resilience allows it to remain vibrant and functional throughout the years, making it a wise investment for any outdoor space.

Constructed from high-quality synthetic materials, resin wicker is designed to resist fading, cracking, and peeling, even in the harshest weather conditions. This ability to endure various climates—from scorching summer heat to bitter winter cold—means that users can enjoy their outdoor furnishings year after year, regardless of where they live.

- In regions with high UV exposure, this type of wicker will not become brittle or discoloured, ensuring that it retains its beautiful appearance.

- Similarly, in areas with heavy rainfall or humidity, the materials used in resin wicker are often treated to be water-resistant, preventing mould and mildew buildup.

Such durability provides peace of mind for homeowners, allowing them to host gatherings or enjoy quiet moments outside without worrying about weather-related damage. Resin wicker furniture exemplifies how thoughtful engineering and quality materials can lead to enduring outdoor solutions.

Weather-resistant

Resin wicker is inherently weather-resistant, allowing it to endure rain, sun, and fluctuating temperatures without fading or deteriorating, making it a perfect option for outdoor living spaces.

This durability is a key advantage for homeowners looking to create inviting, long-lasting outdoor environments. Unlike traditional materials such as natural wicker or wood, which may suffer from mould, rot, or fading over time, resin wicker remains vibrant and intact regardless of the weather conditions. It effectively resists harsh elements, making it suitable for various climates, from humid coastal areas to dry desert regions.

- Natural wicker is prone to wear and tear.

- Wood furniture requires frequent maintenance.

- Metal options often rust or corrode when exposed to moisture.

In contrast, resin wicker combines aesthetic appeal with practical functionality, providing a comfortable, stylish solution for all outdoor furniture needs.

Low Maintenance

One of the major advantages of resin wicker patio furniture is its low maintenance requirements, as synthetic materials do not require regular upkeep like natural wicker or wood, allowing homeowners to enjoy their outdoor spaces without the constant worry of repairs or extensive cleaning efforts.

Unlike traditional wicker or wooden furniture, which can warp, crack, or fade when exposed to the elements, resin wicker offers durability and resistance to moisture and UV rays. This means that owners can simply rinse their furniture with water and mild soap to remove dirt and debris.

Here are some helpful care tips:

- For light cleaning, a soft cloth and soapy water will suffice.

- In the case of stubborn stains, a gentle scrub with a nylon brush can help.

- To maintain its appearance, store furniture indoors during harsh winter conditions.

In comparison, wooden furniture may need regular sanding, sealing, and painting, making resin wicker a more convenient choice for those seeking durability and ease of maintenance.

Lightweight And Easy To Move

The lightweight nature of resin wicker patio furniture makes it easy to move and rearrange, allowing homeowners to adapt their outdoor living spaces according to their needs and preferences.

This flexibility is particularly advantageous when entertaining guests, as it enables quick modifications to seating arrangements or dining setups, ensuring everyone has a comfortable spot.

Imagine hosting a family gathering and, with a simple lift, you effortlessly shift the seating to create an inviting circle around a fire pit. When thunderstorms threaten, being able to swiftly relocate furniture to a sheltered area can protect it from potential damage.

Homeowners can also effortlessly reconfigure their spaces to accommodate various activities such as yoga sessions or children’s outdoor playdates. The ability to transform outdoor environments seamlessly enhances not only functionality but also enjoyment, making the most out of every sunny day and creating memorable experiences.

Versatile Design Options

Resin wicker garden furniture comes in a wide variety of styles and colours, providing versatile design options that can complement any outdoor living space, from contemporary to traditional themes.

The range is truly remarkable, as it spans various designs including sleek modern lines, rustic charm, and even tropical looks that evoke a beachy feel.

Whether you prefer bold colours or muted tones, there's something to suit every taste.

- For a chic contemporary garden, consider deep blues and greys.

- For a cosy traditional patio, earthy greens and browns can enhance warmth.

- Fun, vibrant shades can energise spaces perfect for entertaining.

Resin wicker pieces may feature unique configurations like sectionals or single lounge chairs that adapt seamlessly to any layout.

This flexibility allows individuals to craft personalised outdoor retreats that reflect their style and functionality needs.

How Does Resin Wicker Compare To Other Materials?

When comparing resin wicker to other materials such as natural wicker, metal, and wood, it becomes clear that each material has its own unique set of benefits and drawbacks, making the choice largely dependent on personal preferences and specific uses.

Resin Wicker Vs. Natural Wicker

Resin wicker differs from natural wicker in terms of durability, maintenance, and resistance to the elements, making it a more practical choice for outdoor furniture.

In contrast to traditional materials, which can suffer damage from moisture, sunlight, and temperature fluctuations, resin wicker offers an impressive array of advantages. This synthetic option is crafted to withstand the rigours of outdoor living, meaning it won’t fade, crack, or deteriorate over time. To truly understand why one might prefer resin, it’s essential to consider various elements:

- Care: Resin wicker requires minimal upkeep; a simple rinse with water or a gentle wipe is often enough. Natural wicker, however, may need more careful treatment to prevent mould and mildew.

- Lifespan: Typically, the resin can last up to 10 years or more, whilst natural wicker might last around 5 to 7 years when properly maintained.

- Performance: In terms of performance, resin wicker is resistant to fading and staining, making it ideal for outdoor settings where exposure to the elements is constant.

Choosing resin wicker ensures that outdoor furniture remains both functional and aesthetically pleasing, providing homeowners with a durable and stylish option.

Resin Wicker Vs. Metal

Regarding durability and weight, resin wicker and metal differ significantly, with resin wicker offering a lighter alternative without sacrificing resilience and style.