Are you considering resin flooring for your space but unsure about the costs involved?

This comprehensive guide will walk you through everything you need to know about resin flooring, including the types available, factors that affect the cost, and how it compares to other flooring options.

Discover the benefits of resin flooring and get expert tips on how to save money on your project.

Stay tuned to learn how to get an accurate cost estimate for resin flooring.

What Is Resin Flooring?

Table of Contents

Resin flooring refers to a high-performance flooring system that utilises materials like epoxy resin. It is a durable and versatile flooring option suitable for various applications.

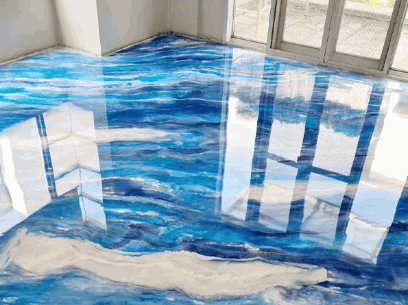

Epoxy resin is a key component in resin flooring, known for its exceptional strength and chemical resistance. This type of flooring is a popular choice for industrial spaces, commercial buildings, and even residential areas due to its ability to withstand heavy foot traffic and harsh chemicals. The resin material used in flooring systems can be customised to meet specific requirements, offering a seamless and smooth finish that is easy to maintain. Other materials, such as polyurethane and acrylic, can also be incorporated into resin flooring to enhance durability and aesthetic appeal.

Dig deeper: How Durable Is Epoxy Flooring

Types Of Resin Flooring

Resin flooring comes in various types, including epoxy, polyurethane, acrylic, and polyaspartic flooring. Each type offers unique characteristics and benefits.

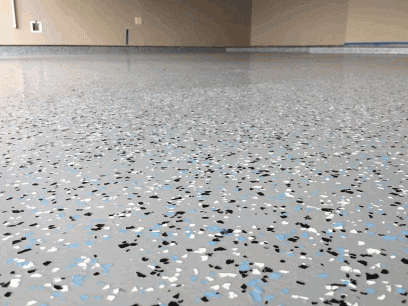

Among these, epoxy resin flooring is a popular choice known for its durability and seamless finish, making it suitable for heavy foot traffic areas such as commercial spaces and warehouses. On the other hand, polyurethane flooring is highly flexible and resistant to chemicals, making it ideal for industrial environments that require frequent cleaning. Acrylic flooring is valued for its decorative possibilities, often chosen for spaces where aesthetics are crucial, such as galleries and showrooms. Finally, polyaspartic flooring stands out for its fast curing time, making it a preferred option for projects that require quick installation and minimal downtime.

Epoxy Flooring

Epoxy flooring is a popular choice known for its high performance and durability. It is commonly used for creating seamless resin floors in commercial and industrial settings.

One of the key features of epoxy flooring is its superior strength and resistance to chemicals, making it ideal for high-traffic areas. The application process for epoxy resin involves mixing the resin with a hardener, which creates a hard, durable surface when cured.

The benefits of epoxy flooring include its seamless finish, easy maintenance, and customisable design options. Epoxy floors are also highly resistant to stains, impact, and moisture, providing long-lasting protection for concrete surfaces.

Maintaining epoxy floors is simple, requiring regular cleaning and occasional resealing to keep the surface looking fresh and vibrant.

Polyurethane Flooring

Polyurethane flooring utilises resilient resin systems to create durable surfaces. It offers a wide range of resin products suitable for different environments and requirements.

The versatility of polyurethane resin systems allows for customisation in terms of colours, textures, and finishes, making it a popular choice across various industries. One of the key characteristics of these resin products is their exceptional resistance to abrasion, chemicals, and UV exposure, ensuring long-lasting performance in high-traffic areas. Polyurethane flooring is known for its seamless installation, creating a smooth and easy-to-maintain surface that is both aesthetically pleasing and hygienic.

Acrylic Flooring

Acrylic flooring is known for its cost-effective nature and quick installation process. It offers a practical resin solution for various projects at manageable resin costs.

One of the key features of acrylic flooring is its durability, making it ideal for high-traffic areas in residential as well as commercial spaces. This versatile flooring option is also resistant to scratches and stains, providing a long-lasting solution that requires minimal maintenance. The installation process is relatively simple, involving the application of resin coatings that adhere seamlessly to the existing floor surface.

Polyaspartic Flooring

Polyaspartic flooring is a fast-curing option that offers a variety of resin types and customisable finishes. It provides versatile resin options for different flooring requirements.

The rapid curing process of polyaspartic flooring is especially advantageous for projects that require quick turnaround times. With options ranging from clear to coloured resins, users can select the perfect resin type to complement their design aesthetic. The customisable finishes allow for unique patterns, textures, and even embedded designs within the flooring. This level of customisation showcases the adaptability of polyaspartic resin solutions in meeting diverse flooring needs, whether in residential, commercial, or industrial spaces.

Factors That Affect The Cost Of Resin Flooring

Several factors influence the cost of resin flooring, including the type of resin, the size and complexity of the area, the extent of preparation work required, and the costs associated with resin installation.

Regarding resin type selection, the choice between epoxy, polyurethane, or acrylic resins can significantly impact the overall project costs. Different resins have varying durability, aesthetics, and maintenance requirements, which can affect both initial expenses and long-term maintenance costs.

The size and complexity of the area to be coated also play a crucial role. Larger areas require more materials and labour, resulting in higher costs. Complex layouts or intricate designs may necessitate specialised techniques, further adding to the expenses.

Preparation work, such as surface cleaning, repairs, and primer application, is essential for ensuring a successful resin flooring installation. The extent of prep work needed can vary based on the condition of the existing substrate, with poor substrate conditions requiring more extensive preparation and thus driving up costs.

Type Of Resin Flooring

The choice of resin flooring type significantly influences the overall cost. Different resin types come with varying price points and installation requirements, affecting the total project expenses.

When considering resin options, epoxy resin typically falls on the lower end of the price spectrum compared to polyurethane or acrylic resin products. While the epoxy resin is more affordable, it may require more intricate installation processes, increasing labour costs. On the other hand, polyurethane resin, although higher in price, offers a more durable and low-maintenance flooring solution, potentially reducing long-term maintenance expenses.

Acrylic resin might have a moderate upfront cost but could require frequent reapplications and upkeep, leading to higher maintenance costs over time. Therefore, choosing the right resin type is crucial in balancing initial expenses with long-term savings for a successful flooring project.

Size And Complexity Of The Area

The square metreage and complexity of the surface to be coated with resin directly impact the project costs. Larger areas or intricate designs may require more materials and labour for successful resin installation.

For resin flooring projects, the size of the area to be covered plays a crucial role in determining the overall expenses. In general, larger surface areas entail more resin material, surface preparation, and labour hours.

Resin surface preparation is a key factor that affects costs, as proper prepping ensures adhesion and longevity of the coating. The intricacy of the design can also influence expenses, as intricate patterns or detailed flooring require more precision and expertise during the resin installation process.

Preparation Work Needed

The extent of preparation work required before resin installation can impact the overall costs. Proper surface preparation, including repairs and priming, is essential for ensuring the durability and longevity of the resin material.

Surface priming plays a crucial role in creating a strong bond between the substrate and the resin material, preventing issues like delamination or peeling. By addressing any surface imperfections through repairs beforehand, the likelihood of future damage or failures in the installed resin is significantly reduced. Thorough preparation steps not only contribute to the overall quality of the flooring but also help in controlling resin costs by minimising wastage and avoiding the need for costly reworks.

Additional Features And Customization

Incorporating additional features and customisation options into resin flooring projects can impact the average cost. Customised finishes, patterns, or special additives may contribute to higher overall expenses.

When considering resin products, the level of customisation plays a significant role in determining the final cost. Tailored designs, unique colour blends, and intricate patterns can elevate the aesthetic appeal of the flooring but often come at a premium price. The inclusion of special additives such as anti-slip properties or enhanced durability features can also affect the project's budget.

Whilst these supplementary features enhance the functionality and visual appeal of resin flooring, they are important factors to consider when estimating the average cost of a tailored resin project.

Cost Comparison With Other Flooring Options

When comparing resin flooring with other options like epoxy, concrete, or vinyl flooring, factors such as resin costs, installation expenses, and the average cost over the floor's lifespan need to be considered.

Resin flooring offers a high level of customisation, making it a versatile option for various spaces as it can mimic the look of other materials like wood or stone.

In terms of durability, resin floors are exceptionally tough, and resistant to scratches, chemicals, and impact, ensuring a longer lifespan compared to alternatives.

Resin floors are relatively low maintenance, requiring simple cleaning routines to keep them looking fresh and vibrant over the years.

Resin Flooring Vs. Epoxy Flooring

The comparison between resin flooring and epoxy flooring involves assessing factors like resin costs, installation complexities, and the specific characteristics of epoxy resin. Each option offers distinct benefits and drawbacks based on project requirements.

Regarding cost, resin flooring options tend to be more cost-effective compared to epoxy flooring. This is because resin floors typically use a combination of various materials like polyurethane, epoxy, or acrylic resins, while epoxy flooring relies solely on epoxy resins.

In terms of installation, epoxy flooring can be more intricate and time-consuming as it requires a meticulous application process to ensure a seamless and durable finish. On the other hand, resin flooring options may offer more straightforward installation procedures depending on the type of resin chosen.

The material properties of epoxy resin, such as its high durability, chemical resistance, and easy maintenance, make it a popular choice for industrial, commercial, and residential applications. Epoxy resin also provides a smooth, glossy finish that enhances the overall aesthetics of a space.

Resin Flooring Vs. Concrete Flooring

Comparing resin flooring with concrete flooring involves evaluating the resin systems used, the complexities of installation, and the overall project requirements. While concrete offers durability, resin solutions provide added benefits in certain applications.

When considering resin systems in flooring projects, it's key to note the seamless nature of resin applications, offering a smooth, joint-free surface ideal for sectors like healthcare. In contrast, concrete floors require joint fillers and can be prone to cracking over time.

The installation process for resin systems typically involves fewer steps and faster curing times, which can shorten project timelines significantly. Resin flooring is available in a wide array of colours and designs, providing architects and designers the freedom to create vibrant and unique spaces.

Resin Flooring Vs. Vinyl Flooring

A comparison between resin flooring and vinyl flooring entails examining the resin options available, the material properties, and the overall performance of each flooring system. Whilst vinyl is cost-effective, resin floors offer enhanced durability and customisation.

- Resin flooring systems are known for their exceptional strength and longevity, making them ideal for spaces with heavy foot traffic or industrial settings. The material options for resin floors include epoxy, polyurethane, and methyl methacrylate, each with distinct properties catering to different requirements.

- On the other hand, vinyl flooring, though economical, may lack the same level of resilience and robustness compared to resin options. Vinyl floors are primarily made of synthetic materials, offering versatility in design and ease of installation.

Benefits Of Resin Flooring

Resin flooring offers numerous benefits, including high performance, durability, and seamless installation. These features make resin floors an ideal choice for demanding environments.

One of the key advantages of resin flooring is its exceptional durability. Resin floors are incredibly durable and can withstand heavy foot traffic, impact, and abrasion without showing signs of wear and tear. This makes them perfect for high-traffic areas such as industrial warehouses, garages, and commercial spaces.

Resin flooring is known for its high-performance properties. It is resistant to chemicals, oils, and solvents, making it a great option for environments where spills are common. The seamless installation of resin floors also eliminates the joints and seams that can harbor dirt and bacteria, ensuring a hygienic and easy-to-clean surface.

How To Get An Accurate Cost Estimate For Resin Flooring?

To obtain a precise cost estimate for resin flooring, factors such as resin costs, installation expenses, and overall resin floors cost need to be carefully evaluated. Engaging with professional installers and obtaining multiple quotes can help in determining the accurate project budget.

When considering resin costs, it's essential to evaluate the quality and type of resin material required for the specific project. Different resin types such as epoxy, polyurethane, or methyl methacrylate vary in cost and performance.

Estimating installation expenses involves assessing labour costs, surface preparation, equipment rentals, and any additional services required for proper installation.

Managing the overall resin floors cost effectively includes factoring in maintenance expenses, durability, and long-term savings provided by high-quality resin flooring solutions.

Tips For Saving Money On Resin Flooring

There are several ways to save money on resin flooring projects, including researching average costs, opting for cost-effective resin systems, and selecting budget-friendly resin products. Comparing quotes from different suppliers can help in securing competitive pricing.

Regarding resin flooring installations, one key tip to keep in mind is to consider the long-term durability of the resin system you choose. Opting for high-quality resin systems that require minimal maintenance can lead to cost savings in the future by reducing the need for frequent repairs or replacements. Efficient resin systems that offer both durability and ease of maintenance can help extend the lifespan of your flooring while keeping maintenance costs low.